End Mills FAQ

What Are the Different Types of End Mills?

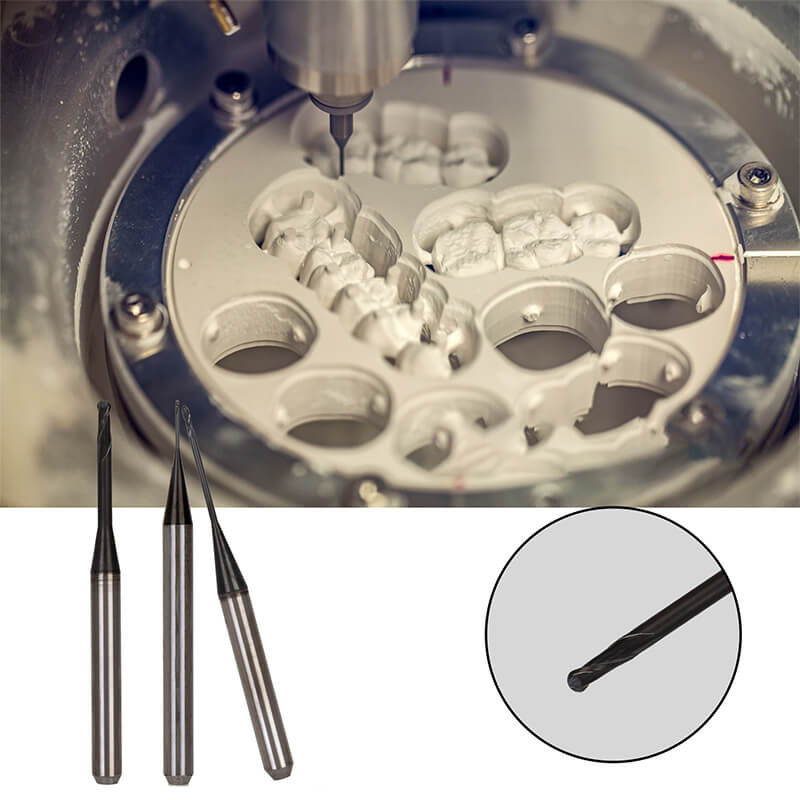

Based on geometry and specific uses, there are many types; flat, ball nose, roughing, finishing, corner radius, and tapered end mill.

How Do I Choose the Right End Mill for My Project?

Choosing the right CNC end cutter requires considerations of the material, cutting type (roughing or finishing), geometry (flutes, shape), machine capability, and surface finish.

How Does End Milling Differ from Drilling?

Drilling cuts axially for cylindrical hole creation, whereas end bits work in both axial and radial directions for slots, grooves, channels, and intricate contours.

Why Is It Called an End Mill?

The name comes from its functionality—it involves cutting edges at the end and sides, which allows for multi-directional material removal.

How Does a Milling Cutter Differ from a Ball-End Mill?

A milling cutter is a broad term including end, face, and slab mills. On the other hand, a ball-end mill is a specific type that involves a hemispherical tip for machining 3D contouring and complex surfaces.

How to Determine the Feed Rate of a Milling Cutter?

You can determine the material feeding rate using the given formula; Feed= Spindle Speed (N) x Chip Load per Tooth (Z) x Flute Count.

WEIX has rich experience in supplying industrial-quality router bits for furniture factories, woodworking tool distributors, and manufacturing and metalworking industries companies across the world. If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, please feel free to contact us. We’d be happy to take your call and discuss specifics with you.

+86-18306105100|info@weixtool.com

Leave A Comment

You must be logged in to post a comment.