Hey everyone! Today we’re breaking down CNC Router Bits versus Regular Router Bits – and why choosing the right one makes or breaks your project. Let’s get into it!

What are CNC Router Bits?

CNC router bits are precision tools designed specifically for use with CNC machines. These specialized tools are optimized for cutting materials like wood, metal, and plastics at high speeds with exceptional accuracy – crucial for automated processes. Regular bits simply aren’t built to handle this level of precision and speed.

Differences Between CNC Router Bits and Regular Router Bits

The critical difference lies in their design. CNC bits are engineered for high-speed, precise cutting, making them ideal for CNC machines. Regular bits aren’t designed to handle CNC operational demands, resulting in less accurate cuts and faster wear.

Materials and Construction

CNC bits typically use high-grade materials like high-speed steel (HSS) or carbide. These ensure effective performance on diverse workpieces, including harder materials like metal and dense woods. Regular bits often use lower-grade materials unsuited for CNC speeds and precision.

Performance and Precision

CNC bits maintain high cutting speeds and sharpness for extended periods. With proper maintenance, they deliver consistent, high-quality results. Regular bits used in CNC machines dull quickly, causing inefficient and inaccurate outcomes.

Why Regular Router Bits Shouldn’t Be Used in CNC Machines

Using regular bits in a CNC machine can lead to a number of issues, including poor quality cuts, increased wear on the tools, and potential damage to both the machine and the workpiece. CNC bits are specifically designed to handle the high-speed, automated operations of CNC machines.

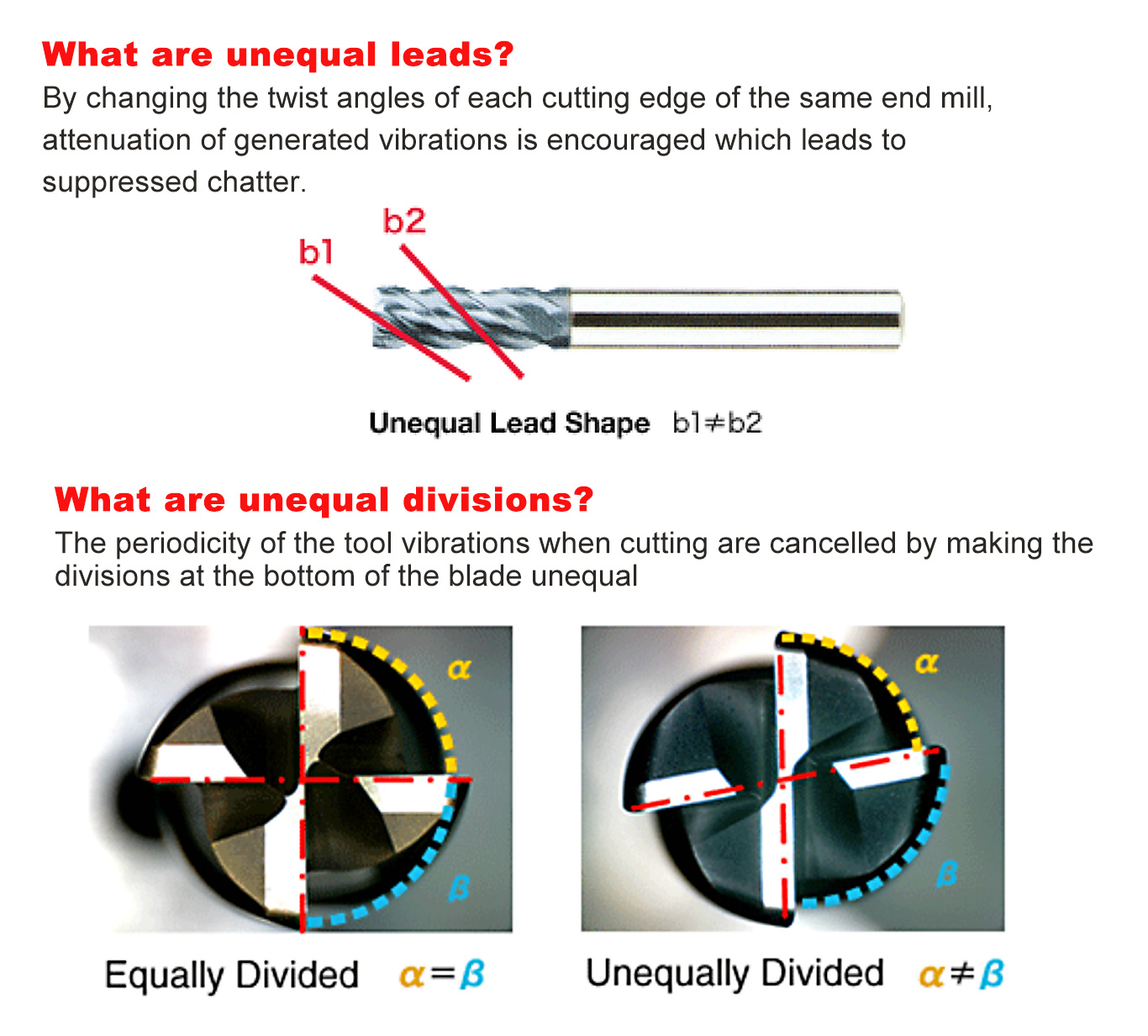

Potential Damage to Machine and Workpiece

Regular bits are not built for the high-speed rotation and precision required in CNC machining. Using these tools can result in excess vibration, overheating, and inaccuracies that damage both the workpiece and the machine itself. For instance, using a regular bit on a harder material like metal can cause the bit to wear down prematurely, resulting in poor-quality cuts.

Inefficiency and Inaccuracy

Regular bits in CNC machines cause inefficiencies and inaccuracies. CNC bits ensure automated precision for faster, accurate cuts. Regular bits compromise detail and slow production.

Choosing the Right CNC Bits for Your Project

Choosing the right CNC bits for your project is essential to achieving high-quality results. Factors like material type, cutting geometry, and application should all be considered to ensure that you are using the correct tool for the job.

Factors to Consider

When selecting CNC bits, take into account the type of material you’re working with, as well as the desired cut type and finish. For example, spiral bits are great for clean cuts on wood, while straight bits are ideal for heavy-duty cuts. Understanding the material properties and cutting needs will help you choose the right tools for your project.

Types of CNC Bits

There are many types of CNC bits, each suited to different tasks:

1.Spiral bits are ideal for smooth finishes and efficient chip removal.

2.Straight bits are used for heavy-duty cutting, like sign-making.

3.Up-cut bits lift chips away from the workpiece, preventing burn marks.

4.Down-cut bits push chips downward, providing a clean edge on the top surface.

5.Compression bits combine up-cut and down-cut designs for a clean finish on both sides of laminated materials.

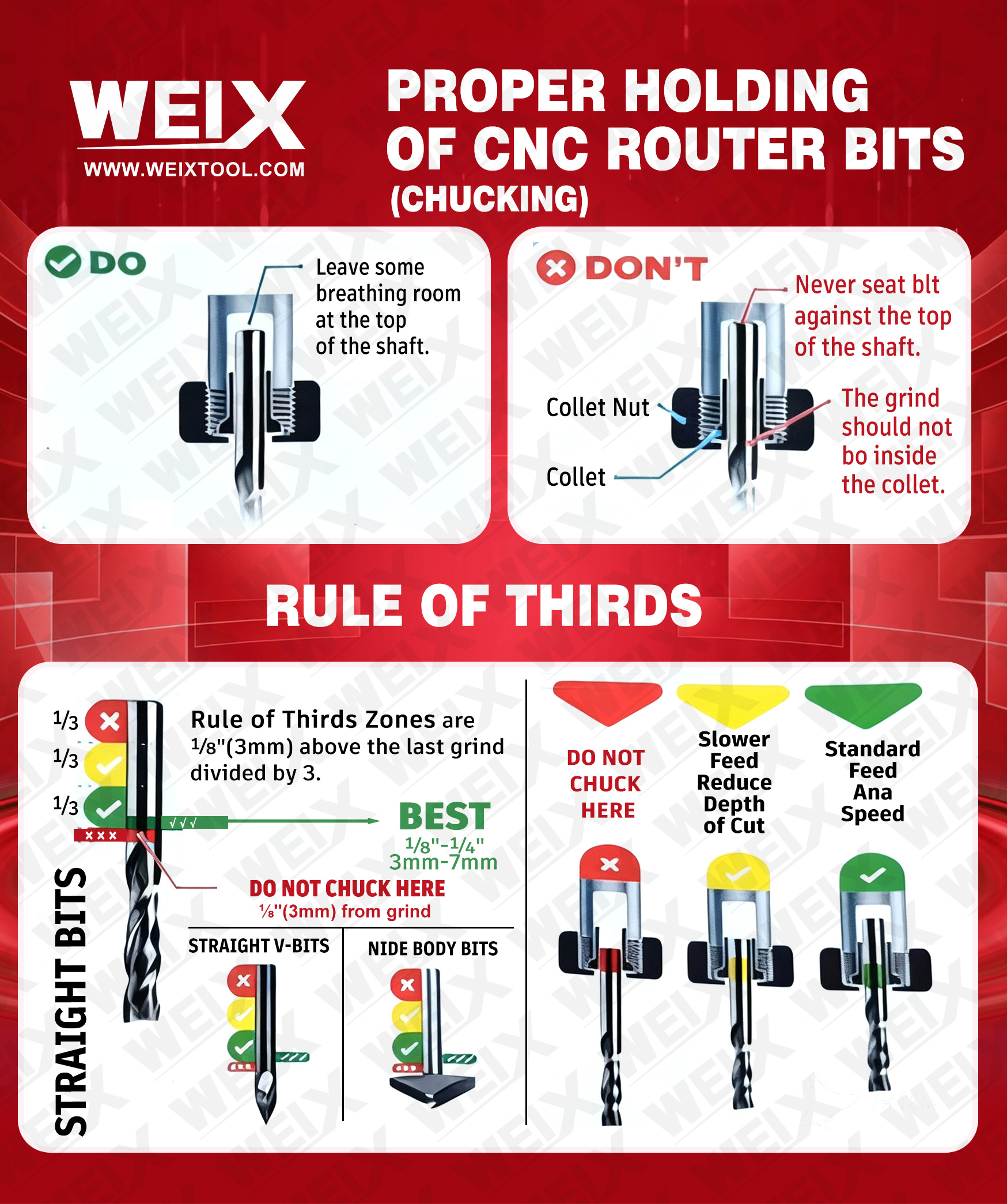

Proper Maintenance and Care for CNC Bits

Maintaining CNC bits is essential for ensuring long-lasting performance. Regular inspections, cleaning, and proper storage can extend the life of your tools and ensure optimal cutting efficiency.

Tips for Prolonging Lifespan

To extend the life of CNC bits, focus on proper chip removal during cutting, avoid excessive heat buildup, and inspect the tools regularly for wear. These practices can help maintain the sharpness of your bits and prevent premature wear.

WEIX has rich experience in supplying industrial-quality router bits for furniture factories, woodworking tool distributors, and manufacturing and metalworking industries companies across the world. If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, please feel free to contact us. We’d be happy to take your call and discuss specifics with you.

+86-18306105100|info@weixtool.com

Leave A Comment

You must be logged in to post a comment.