Hey everyone! Today we’ll dive deep into the world of what is CNC End Mill ?

Simply put, End Mill is one kind of milling cutter to do the process of removing metal by CNC Milling machines.

There are various diameters, flutes, lengths, and shapes to choose from. Basically, users choose them according to the material of the workpiece and the surface finish required for the workpiece.

So, let’s start by introducing the appearance of the End Mill, including the shapes, flutes, and coating.

1. End Mill Shapes

WEIX TOOLS provides other shapes End Mill, visit hight performance Solid Carbide End Mills & Cutters Tools.

A. Square End Mill:

Also known as a “flat end mill,” this is the most common type and can be used for a variety of milling applications, including side milling, profiling, and plunge cutting. WEIX TOOLS also offers HPC (high-performance cutting) square type with a little chamfer for better slotting, ramping, and can do trochoidal milling.

B. Ball Nose End Mill:

The end flute of Ball Nose End Mill is with no flat bottom. It is ground with a full radius equal to half of the tool diameter. For example, you may say 5R to a 10mm ball nose end mill. Ball nose mills are used for contour milling, shallow pocketing, and contouring applications, etc. They are especially good for 3D contouring because they leave a nice rounded edge.

C. Corner Radius End Mill:

Imagining there is a radius form at a sharp corner of a square end mill, that’s a corner radius milling tool. These are commonly used to mill mold & die as you don’t need to use nearly as many tool changes to get flat-bottom pockets and rounded contours.

D. Taper End Mills:

Also known as pencil end mills and conical end mills, these names are used for describing the shape of its flute. They can produce grooves, holes, or side-milling with a slope angle.

E. Long Neck End Mill:

The design can avoid the interference between the tool and workpiece by reducing the shank diameter behind the flute, which is ideal for deep slotting (deep pocketing).

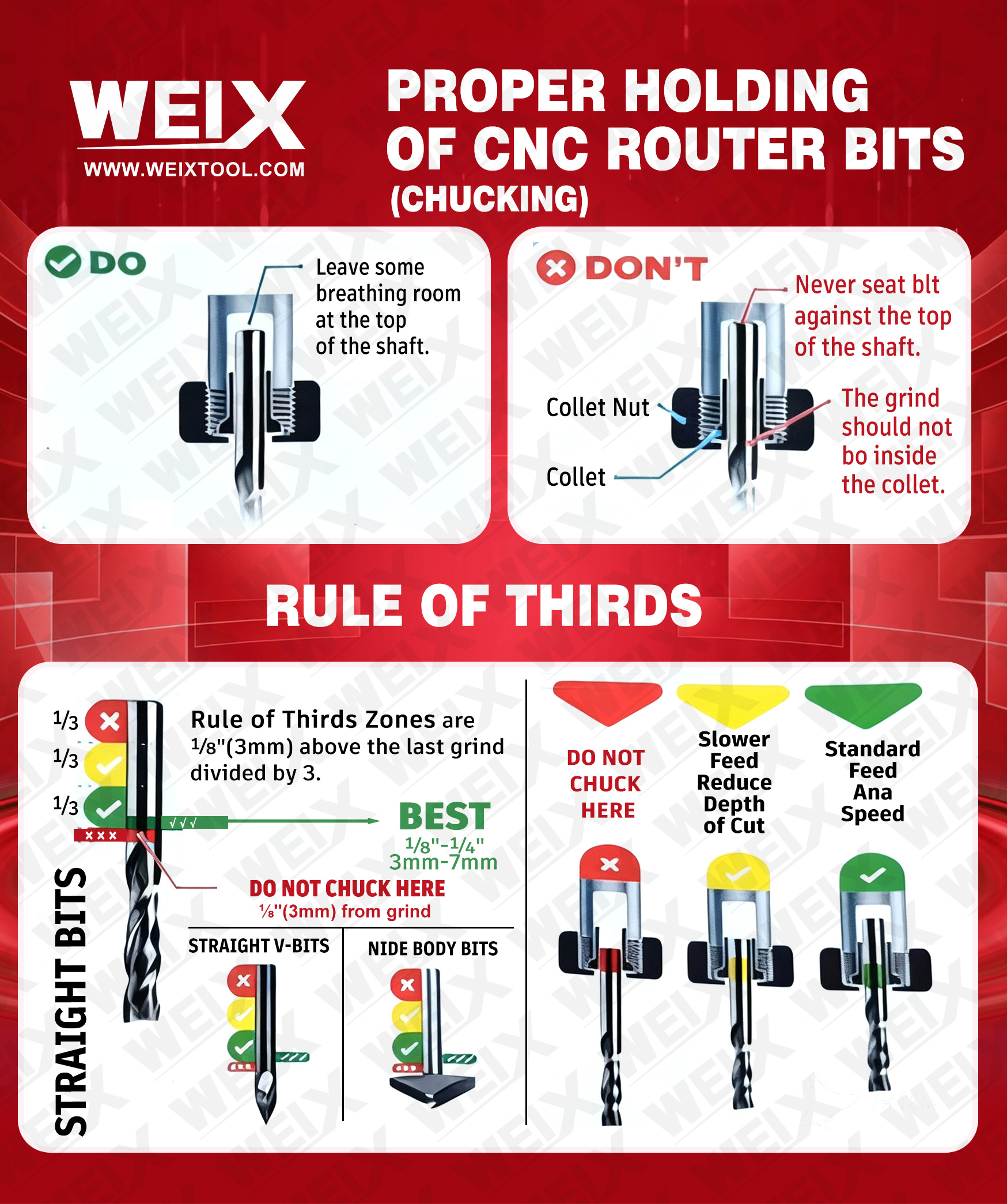

F. CNC Router Bits:

CNC router bits are the cutting tools that work on a CNC router. They usually can be made to cut non-ferrous metals (soft materials), such as aluminum, brass, copper, MDF, plastic, PVC, wood, and more.

2. End Mill Flutes

Which part is the flute?

The answer is the spiral channels on an end mill. And the design of the flute also will determine which materials you can cut.

The most common options are 2, 3, or 4 flutes. Generally, fewer flutes mean better chip evacuation, but at the expense of surface finish. More flutes give you a nicer surface finish, but worse chip removal.

3. End Mill Coatings

What does coating do?

To put it simply, the purpose of the coating is to extend tool life and improve performance.

Coating is like the clothes of an end mill. On different occasions, it needs to be worn the right clothes. For example, people need to wear a spacesuit when they are in outer space, and a swimsuit when they swim. Therefore, depending on your processing conditions, it will affect what coating you need to choose.

WEIX has rich experience in supplying industrial-quality router bits for furniture factories, woodworking tool distributors, and manufacturing and metalworking industries companies across the world. If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, please feel free to contact us. We’d be happy to take your call and discuss specifics with you.

+86-18306105100|info@weixtool.com