Applications of Corn Teeth End Mill

Corn teeth end mills (also called corn mills, ridge cutters, gong cutters, or pineapple cutters) are typical end mills designed for industrial milling. Unlike milling bits that only cut axially, they can cut both axially and radially.

Made of high-grade solid carbide, these end mills feature sharp teeth for high-precision, bright polishing. They offer high hardness, wear resistance, strength, bending resistance, and long tool life, performing reliably even in harsh, high-temperature conditions. Their surface is more abrasive than regular end mills, with a wider range of sizes/shapes, and polished surfaces reduce friction to boost machining efficiency and production speed.

They are compatible with 3-axis, 4-axis, and 5-axis milling machines. 3-axis cutters allow flexible table positioning and vertical/horizontal cutting via bidirectional spindles. 4-axis models (with a turnaround table) are used in automotive and aviation industries. 5-axis cutters combine 3 linear and 2 rotational axes, configurable by model.

Key Applications

Metals: Process heat-resistant alloys (titanium, stainless steel), aluminum, iron, copper, and mold components. Coated variants excel at tough metal machining, while their tooth design enhances cutting capacity for hard materials like stainless steel.

Non-metals: Cut synthetic materials (synthetic stone, bakelite, wood, epoxy, fiberglass, insulating materials), High-Density Fiberboard (HDF), HDF composite board, hardwood, carbon fiber, and fiberglass. 2-flute deep-flute models optimize chip evacuation for hardwood; specialized coatings handle abrasive materials like carbon fiber and fiberglass.

Electronics: Widely used in circuit board fabrication for milling copper, drilling component holes, and cutting custom board shapes—eliminating tool changes in some cases. Post-milling, boards need corrosion protection (e.g., liquid tin, solder masks) to prevent copper tarnishing/oxidation.

CNC Machining: Ideal for complex 3D cutting of materials (metal, plastic, wood, ceramic, composite) via programmed instructions, enabling efficient, operator-free processing of HDF and HDF composite boards.

Tool Features

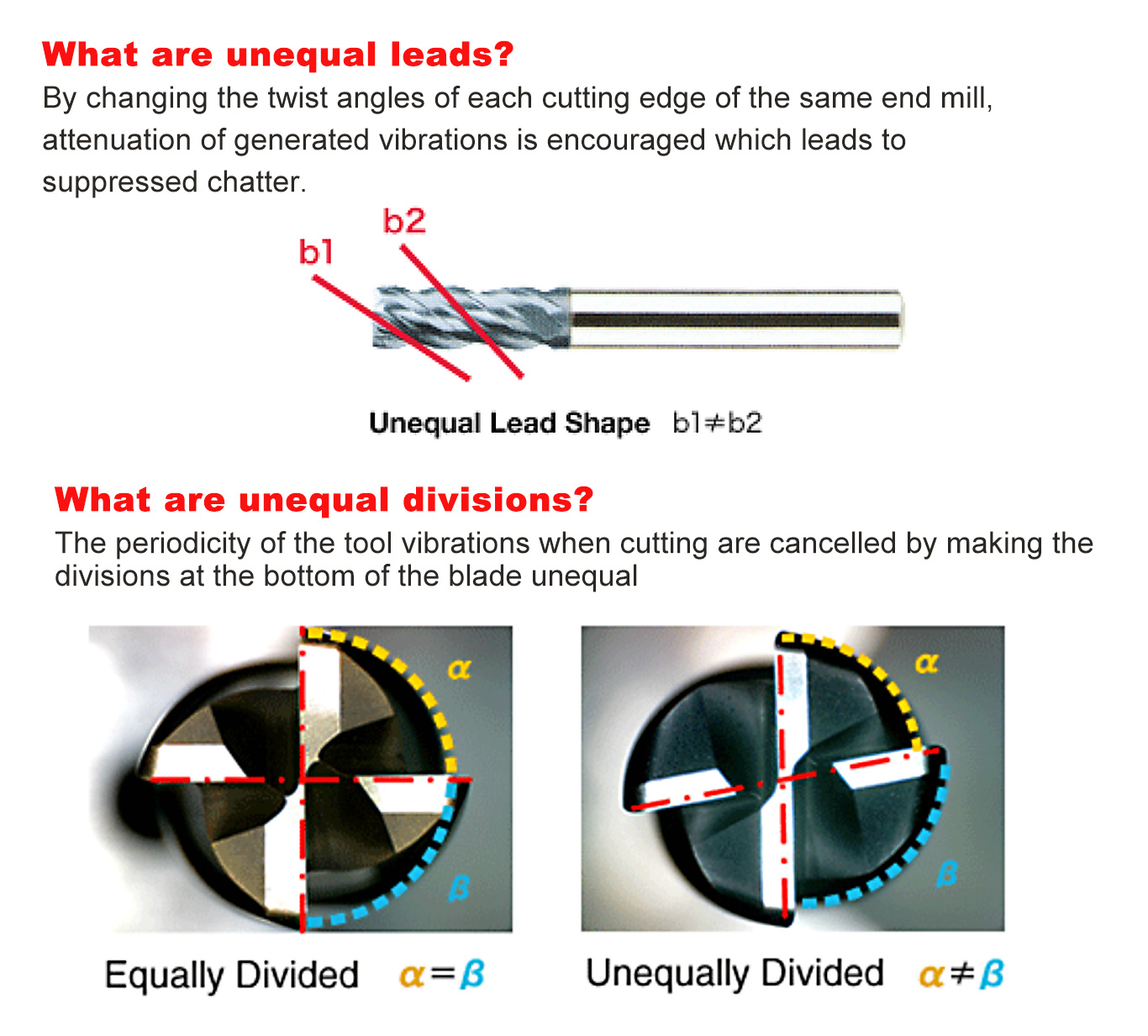

Flute count: More flutes deliver precise finishes and less vibration at high speeds; fewer flutes offer better chip clearance for high-volume, high-speed plunging, slotting, and roughing.

Design: Smooth, wide flutes facilitate chip removal; HELICA heat-resistant coatings enable high-speed processing; square ends create square gaps/pockets/edges; center cuts allow plunge cutting.

In summary, corn teeth end mills process, cut, and shape various mechanical components, with configurations ranging from simple cylindrical/conical to complex hemispherical. At WEIX, we customize corn teeth end mills to meet each customer’s unique requirements.

+86-18306105100|info@weixtool.com

Leave A Comment

You must be logged in to post a comment.