Choosing the right circular saw blade hinges on its tooth design and count, which are tailored to different cutting tasks. This guide breaks down the key factors to help you pick the ideal blade for your projects.

Tooth Count

Tooth count refers to the total number of teeth on a blade. More teeth deliver smoother, cleaner cuts but demand a more powerful saw motor. The right count depends on your cutting application and material:

- Ripping: Requires fewer teeth (24–40), designed for cutting along the wood grain.

- Crosscutting: Needs more teeth (60–80) for slicing across the grain with precision.

- Combination/general-purpose: A 40–60 tooth blade works for both ripping and crosscutting.

Material also matters: use fewer teeth for hardwood and more teeth for softwood to achieve smoother cuts.

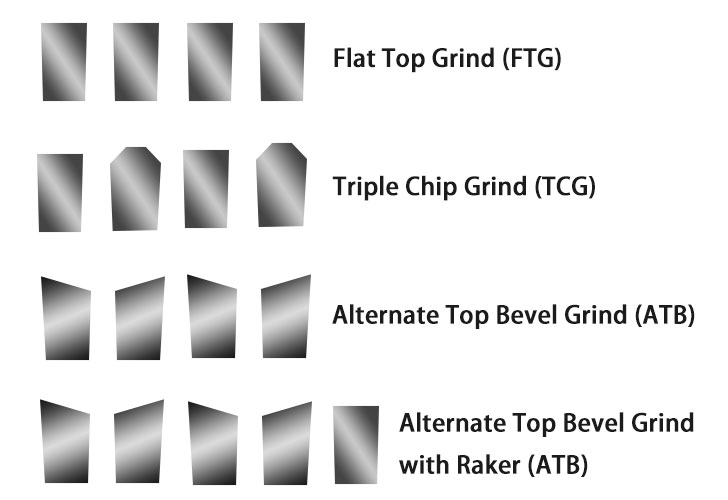

Tooth Grind

Tooth grind describes the shape of blade teeth, another critical factor for optimal performance. Here are the most common types:

-

ATB (Alternate Top Bevel)Teeth feature alternating 10–20° beveled tops, making this a versatile all-purpose grind. Ideal for crosscuts and effective for rip cuts, it works well with solid wood and veneered plywood.

-

ATBR (Alternate Top Bevel with Raker)An all-purpose grind with sets of 5 teeth: 4 ATB teeth plus 1 flat-top raker. Suited for both crosscuts and rip cuts.

-

TCG (Triple Chip Grind)Combines a trapezoid tooth with a flat-top tooth, minimizing sawdust and tear-out. Perfect for cutting MDF, laminates, chipboard, hardwood, plastics, solid surfaces, and non-ferrous metals.

-

FTG (Flat Top Grind)Features flat-top teeth, engineered for fast, efficient ripping. Its flat design also makes it ideal for grooving tasks.

Choose Weixtool for Reliable Blades

Weixtool is a trusted supplier of industrial-grade circular saw blades, with extensive experience in global trade. If your business is seeking a dependable circular saw blade partner, contact us at info@weixtool.com today.

+86-18306105100|info@weixtool.com

Leave A Comment

You must be logged in to post a comment.