A collet chuck is a versatile, precise machining tool ideal for CNC turning, milling, grinding, and other applications requiring secure workpiece clamping. Preferred over standard clamps for uniform gripping force and excellent concentricity, it boosts machining accuracy and finish. Below we cover its definition, types, advantages, ideal use cases, and selection tips.

1. What Is a Collet Chuck?

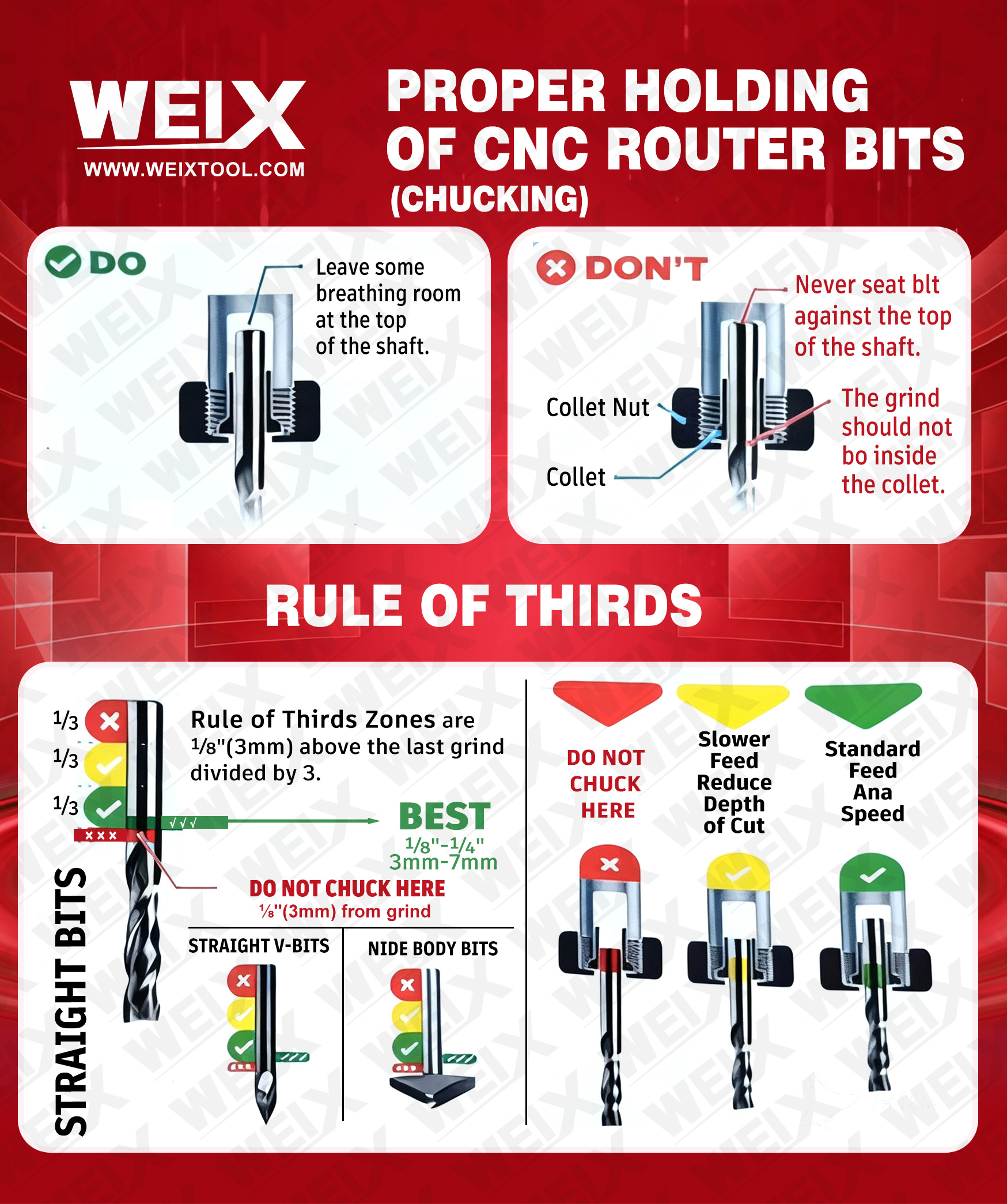

A collet chuck is a specialized clamping device using a tapered cylindrical collet to hold workpieces or tools. When engaged, the collet tightens inside the chuck body for a secure grip. Unlike traditional chucks, it distributes clamping pressure evenly around the workpiece, minimizing runout for more accurate holding.

Common types include:

ER Collets: Most widely used for small-to-medium parts and CNC operations.

5C Collets: Ideal for manual lathes and high-precision small workpieces.

R8 Collets: It is commonly used for holding milling machine tools and for precision machining tasks.

Capto Collets: For high-performance CNC turning/milling, offering superior rigidity and precision.

2. Advantages of Using a Collet Chuck

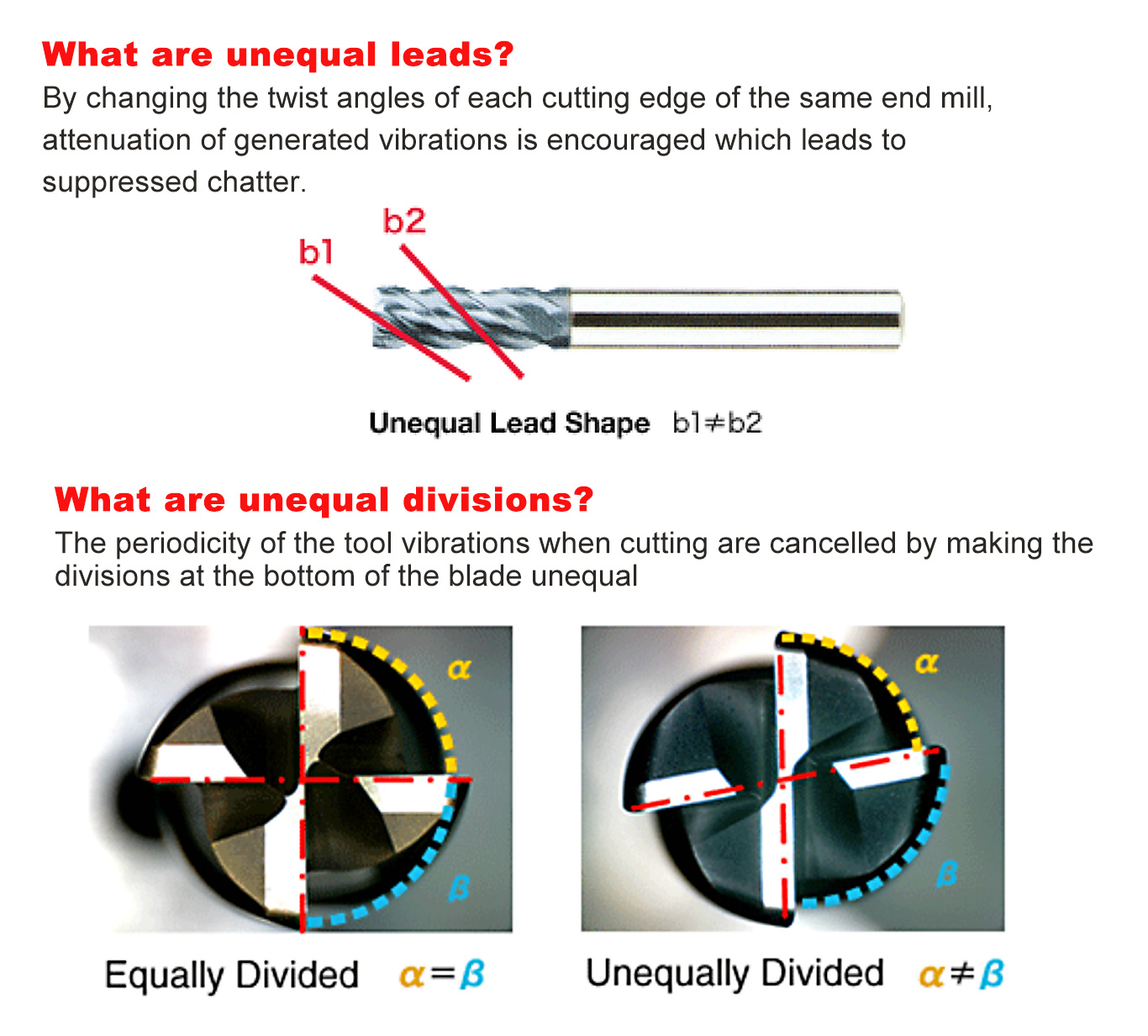

① Precision and Accuracy:Exceptional precision with uniform gripping minimizes runout, critical for tight tolerances and high-quality finishes in precision machining.

②Fast Setup and Tool Changes:Enables quick tool/workpiece swaps (seconds) to reduce production downtime—ideal for high-volume manufacturing.

③ Versatile Holding:Securely clamps round, hexagonal, square, and other shapes, suitable for diverse industries and tasks.

④Reduced Workpiece Distortion:Even pressure distribution prevents deformation, making it perfect for delicate or thin-walled components.

⑤High Clamping Force:Delivers strong clamping to keep workpieces stable during machining, especially critical for high-speed operations.

3. When to Use a Collet Chuck?

①Critical Precision Requirements:Ideal for aerospace, medical device, and high-precision automotive manufacturing, where tight tolerances are non-negotiable.

②High-Speed Machining:Minimizes vibration/deflection for stable high-speed milling, turning, or grinding—improving quality and efficiency.

③Need for Quick Tool Changes:Saves time in high-production or multi-part jobs with easy tool swaps, no full chuck disassembly required.

④Small-to-Medium Workpieces:Versatile collet sizes enable precise clamping of small components, with gentle yet firm pressure for fragile materials.

⑤ Minimal Workpiece Distortion:Even pressure prevents bending/warping of delicate or intricately shaped parts.

⑥Milling and Drilling Operations:Provides stable, accurate tool holding for clean cuts and precise holes when using cutting tools, drills, or end mills.

4. How to Choose the Right Collet Chuck

①Material Compatibility:Select based on workpiece material: ER collets for soft metals/plastics; 5C/R8 collets for harder metals.

②Workpiece Size:Ensure the collet accommodates your component’s diameter for secure clamping.

③Machine Compatibility:Choose a collet chuck matching your machine’s spindle and specifications.

+86-18306105100|info@weixtool.com

Leave A Comment

You must be logged in to post a comment.